Четыре треугольника. Угол вершины 60° 12-spline flange Screw Head - Spline.svg

The 12-spline flange screw drive has twelve splines in the fastener and tool. It consists of 12 equally spaced protrusions, each with a 60° angle. It is achieved overlaying 4 equilateral triangles, each one rotated 30° over the previous one. The spline drive was part of the obsolete, U.S-designed Optimum Metric Fastener System and was defined by ASTM B18.2.7.1M, which was withdrawn in 2011,[65] making the spline drive obsolescent. Spline drives were specified for 5, 6.3, 8, 10, 12, 14, 16, and 20 mm size screws[66]. Its primary advantage is its ability to resist cam out, so it is used in high-torque applications, such as tamper-proof lug nuts, cylinder head bolts, and other engine bolts.

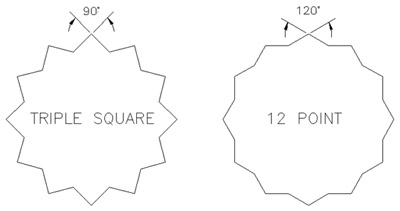

Три квадрата Угол вершины 90° Triple-square Screw Head - Triple Square.svg

The triple-square, also known as XZN, is a type of screw drive with 12 equally spaced protrusions, each ending in a 90° internal angle. Common sizes are 6, 8, 10, and 12 mm. The name derives from overlaying three equal squares to form such a pattern with 12 right-angled protrusions (a 12-pointed star). In other words, three Robertson squares are superimposed at a successive 30° rotation. The design is similar to that of the double-square—in both cases, the idea being that it resembles a square (Robertson) but can be engaged at more frequent angles by the driver bit. These screws can be driven with standard Robertson bits.

The 12-pointed internal star shape superficially resembles the "double hex" fastener head, but differs subtly in that the points are shaped to an internal angle of 90° (derived from a square), rather than the 120° internal angle of a hexagon. In practice, drivers for the fasteners may or may not interchange, but should be examined carefully for proper fit before application of force. A hex key should not be used where a key of square cross-section is the correct fit.

Triple-square drive fasteners have been used in high-torque applications, such as cylinder head bolts and drive train components. The fasteners involved have heads that are hardened and tempered to withstand the driving torque without destroying the star points. They are commonly found on German vehicles such as Audi, BMW, Opel, Mercedes, Porsche and Volkswagen.[43]

Два шестигранника. Угол вершины 120° 12-point Screw Head - 12-Point external.svg

A 12-point screw drive uses two overlapped hexagon shapes, one rotated by 30º. Standard 12-point hex socket bits and wrenches fit these screws. The screw heads are typically flanged, and may fit into standard Allen hex socket cap screw counterbores molded or machined into parts to be fastened. Compared to Allen hex sockets, the advantages of these bolts include higher torque capability and the lack of a recess to trap water. A disadvantage is the extra cost involved in forming the heads.